Advantages of unit application:

1. The project adopts the central control cooling and heating mode, which improves the quality of edible mushrooms by simulating the optimal growth environment required by edible mushrooms (including temperature, humidity, CO2 concentration and light), realizes year-round production and avoids the disadvantage of traditional mode of “relying on the sky to eat”.

2. The entire project covers an area of about 350 acres of mushroom sheds, will be divided into four blocks independently of the centralized control of refrigeration, and the machine room is basically located in the middle of each block, can effectively shorten the overall cost of the project pipeline to reduce the initial investment, while greatly reducing the head of the pump to reduce the operating costs of the system;

3. The project adopts Qingfeng frequency conversion magnetic levitation chiller as the refrigeration host, whose power accounts for 50%-60% of the whole system, the unit has a number of advantages;

4. The growth of edible fungi has requirements for the temperature, humidity, CO2 concentration, light and pergola of the greenhouse. At the same time, different growth stages of temperature, light and humidity parameters of different control points. Qingfeng intelligent control system for edible fungus can meet the demand for automatic adjustment of parameters at different growth stages of edible fungus, without the need for personnel to adjust the set parameters back and forth. This realizes the standard of automated intelligent production of edible fungus factory, improves the efficiency, reduces the equipment regulating personnel and lowers the labor cost. In addition, the control system has corresponding measures in energy saving, making full use of the outdoor temperature to save energy and reduce consumption, and has a data storage function.

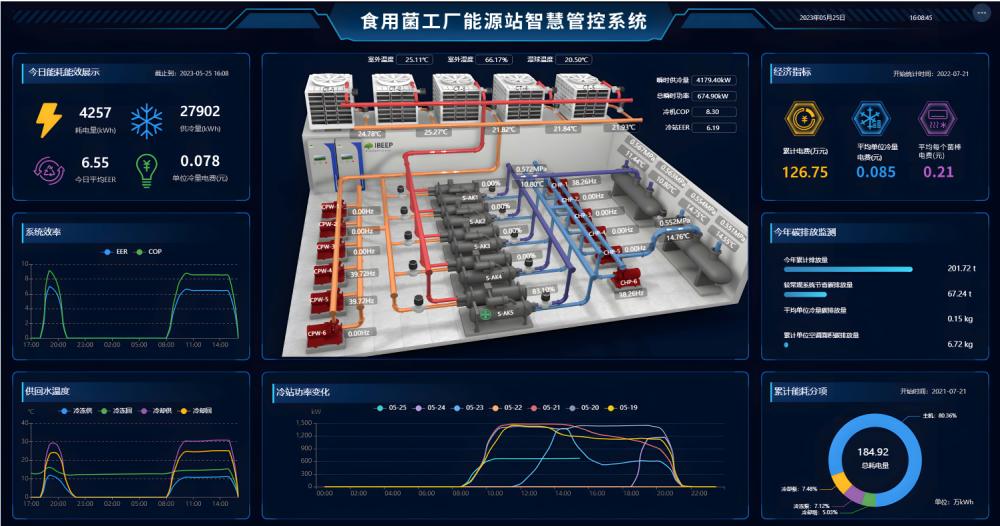

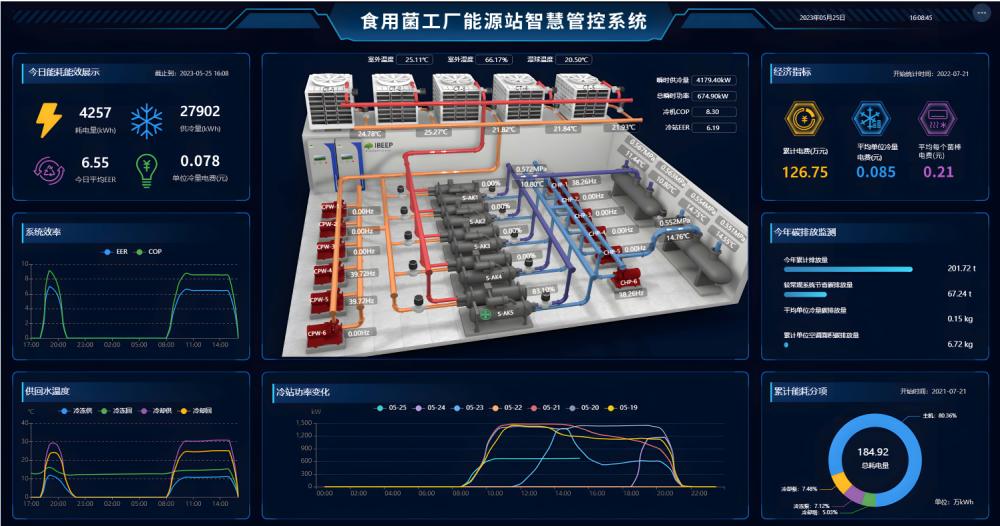

5. The project is equipped with a remote monitoring system, which can monitor the parameters of each room via PC or cell phone and realize remote adjustment when necessary. At the same time, alarm information will be pushed to the designated personnel in time when there is a fault in the on-site room, which improves the response time for troubleshooting and guarantees the safe growth of edible mushrooms. For rooms with the same function, only the parameters of one of them need to be set, and the parameter setting of all rooms can be realized through the one-key override function, thus reducing the operation time of the regulators, improving the work efficiency and reducing the labor cost.