Ningbo digitalization of the South American white shrimp breeding integrated aquaculture project

The project planning land of 1,000 acres, with a total investment of 660 million yuan, of which 120 million yuan of estimated investment in the first phase, covering an area of 150 acres, mu average investment of 800,000 yuan.

The project adopts 5G Internet of Things + recycled water + fully automated modern shrimp farming mode, mainly the construction of high-performance constant-temperature aquaculture workshop, PVC aquaculture tanks, equipped with all-weather water recycling integrated purification system, automatic water quality monitoring system, pure oxygen oxygenation system, biological purification of bacterial cultivation system, automatic water temperature control system, automatic feeding system, air purification system, bio-floculation control system, tail water treatment system. The whole production process using big data monitoring and control system, to achieve the South American white shrimp farming all intelligent, and through the continuous self-learning and automatic correction of the system, to calculate the best conditions for the growth of cultured species, to create the most suitable environment for the cultured species, to maximize the output rate per unit area.

Required Features:

1. There are 8 workshops in this project, each workshop discharges 1200 tons of wastewater and replenishes 1200 tons of fresh water every day, and the whole factory area has 9600 tons. 2;

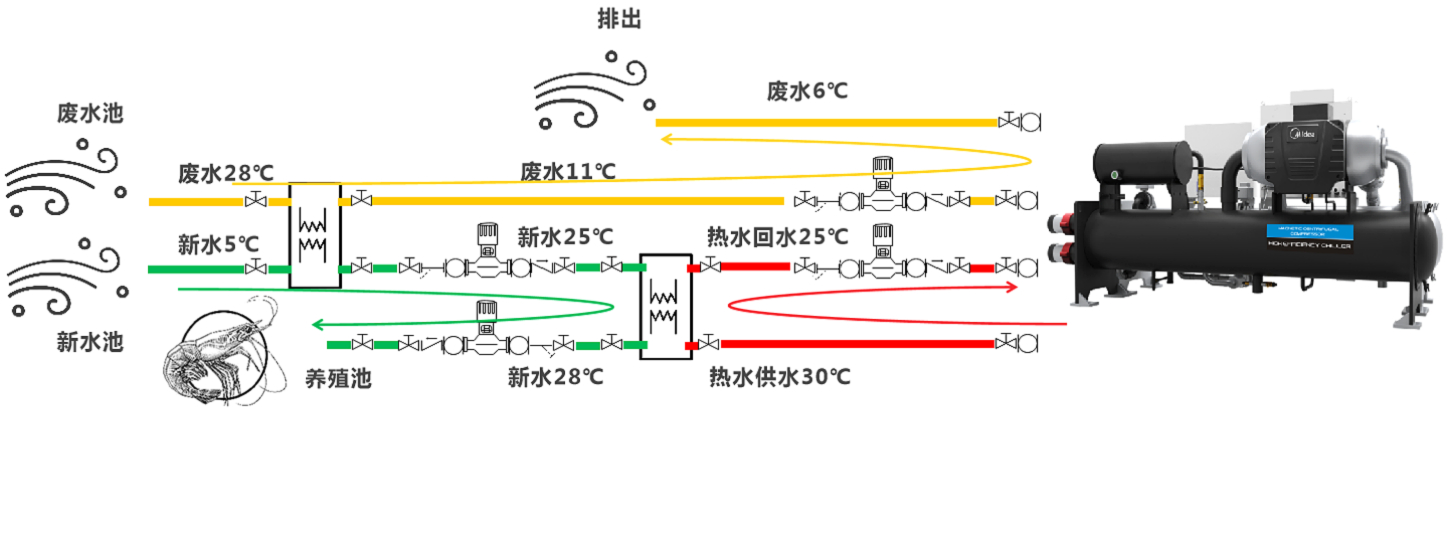

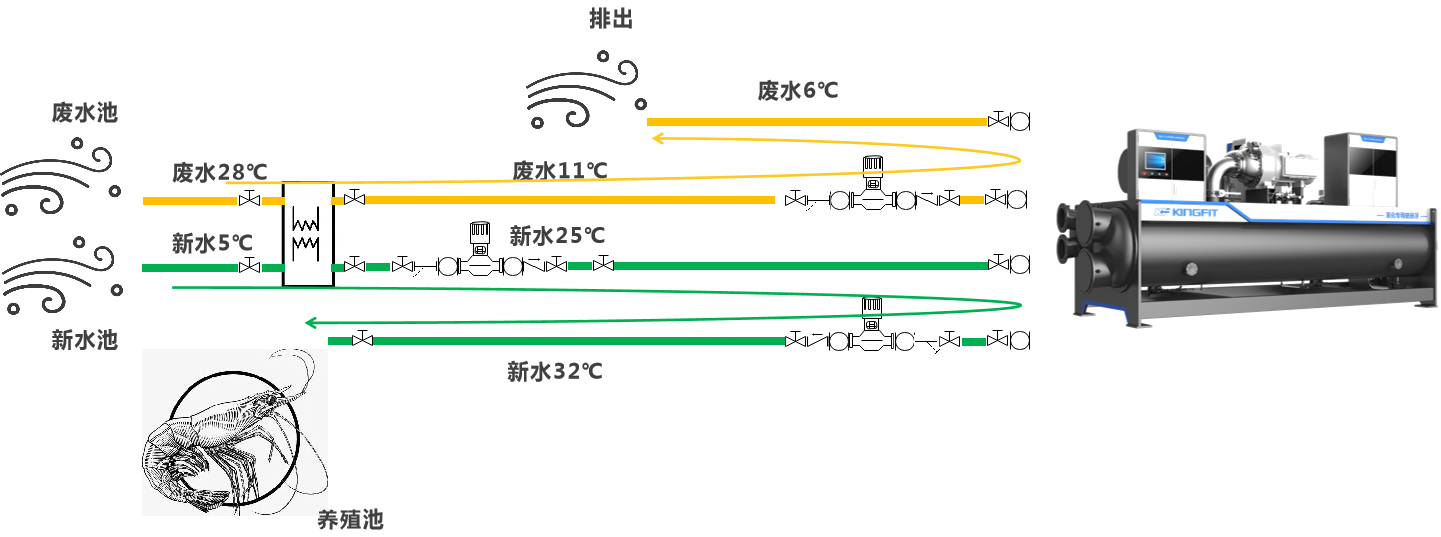

2. 9600 tons of 28℃ wastewater and 5℃ seawater fresh water are heat exchanged using plate heat exchanger every day, discharging wastewater at 11℃ and fresh seawater make-up water is warmed up to 25℃;

3. water source heat pumps use the heating side to heat 25°C fresh water to 28°C to 30°C, and the heat source side of the water source heat pumps utilizes the discharged 11°C wastewater during extreme weather.

4. Originally, a water source heat pump manufacturer had been selected, but the indirect heat transfer method was used, and the direct heating method was used for want of more energy efficiency.